We Design Some of the Most Powerful,

Efficient & Reliable Electric Thrusters in the World

Electric Thrusters are used on Remotely Operated Vehicles (ROVs), AUVs, Submarines and basically any underwater device that needs Electric Propulsion to move underwater. We have many different off the shelf electric thrusters and we also can customize solutions/Systems for R&D programs or prototype vehicles, small or large. These thrusters can be precision matched to each application at very minimal cost. We also have many Electric Thrusters that are not listed on the website.

Electric Thrusters are used on Remotely Operated Vehicles (ROVs), AUVs, Submarines and basically any underwater device that needs Electric Propulsion to move underwater. We have many different off the shelf electric thrusters and we also can customize solutions/Systems for R&D programs or prototype vehicles, small or large. These thrusters can be precision matched to each application at very minimal cost. We also have many Electric Thrusters that are not listed on the website.

In order to properly evaluate different thruster systems, it is important to understand and consider the size of the units, as the propeller diameter has a big impact on the level of thrust produced by each horsepower of input. The necessary data is easily available on most specification sheets from each manufacturer to obtain different values of thrust with corresponding input power. In some cases, input power is only provided indirectly by giving Hydraulic Pressure and Flow Rate for hydraulic thrusters, or for electrical motors by giving voltage and current. All of these parameters will provide values of input power at that thrust level.

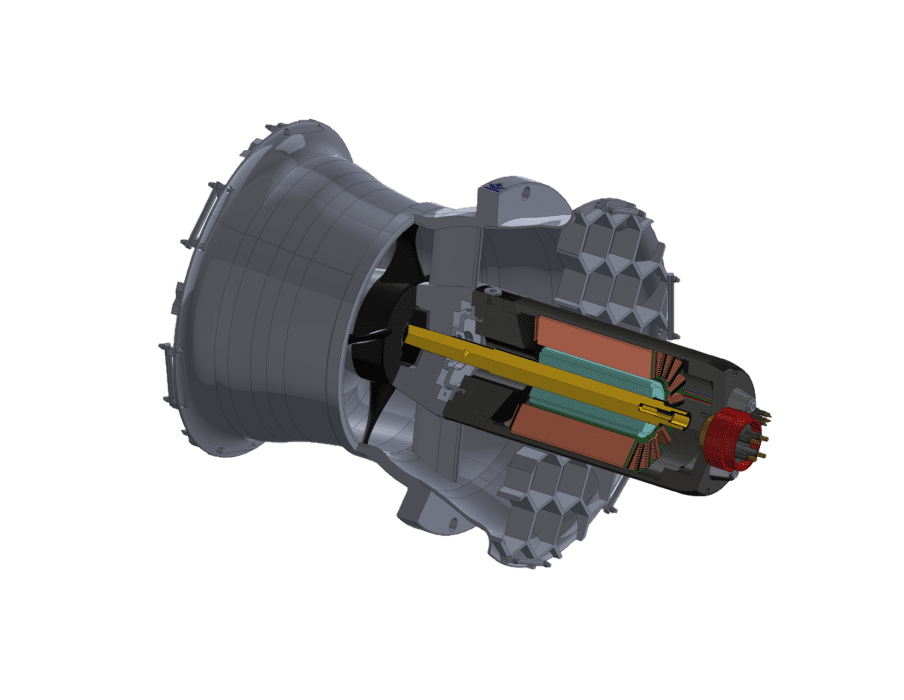

Brushless DC Electric Thrusters

– Being of superior hydrodynamic design, the venturi shape of the 1002 & 1004B Thrusters are ideally suited for Electric Drive. The Venturi shape of the thruster duct is used to allow a higher rotation speed with smaller diameter and higher pitch-to-diameter ratio props. This increases the efficiency and the rpm and allows the prop to turn faster for the same power.

– Customized Solutions/Systems for R & D Programs or Prototype Vehicles, small or large. These electric thrusters can be precision matched to each application.

– Streamlined Brushless DC, oil filled and pressure balanced direct drive electric submersible motors. Capable of going to full ocean depth.

– Independently Tested Off-The-Shelf Units

– The electric motors are available with no feedback or with resolver or hall effect for accurate servo control.

All our Electric Motors have a 3 tier seal system. An external motor seal to keep large debris out, a specially designed internal/external seal that is capable of sealing the motor on its own and finally a Silicon Carbide Face Shaft Seal that is the main seal. This offers a large safety margin to prevent water leaks into the motor or oil out.

All of our thrusters are very efficient and are proven models that have a solid track record. All motors are streamlined and limit flow blockage. Innerspace’s Electric Motors are direct drive and do not require an Adapter Shaft, extra Bearings, gears and or a gear box. Innerspace Thrusters provides the most reliable products currently in the marketplace.

Electric Thrusters

THE 1002 SERIES ELECTRIC THRUSTERS

THE 1002 SERIES ELECTRIC THRUSTERS

The 1002 Series Electric Propulsion Systems provide the ultimate in reliability & efficiency. The Electric Motor efficiency is over 90% for the 14,000 Series Electric Motors. The 1002 Electric Thruster produces a high level of thrust in the forward direction and 90+% in reverse operation. Learn more about our 1002 Series Electric Thrusters here.

THE 1004B SERIES ELECTRIC THRUSTERS

THE 1004B SERIES ELECTRIC THRUSTERS

The 1004B Series Electric Propulsion Systems are a half scale model of the 1002 Electric Thrusters. The standard electric motors are designed to operate from 110-300 VDC with a Bollard Thrust of 50 to 70 lbsf depending on the model chosen. Learn more about our 1004B Series Electric Thrusters here.

THE H106 SERIES ELECTRIC THRUSTERS

THE H106 SERIES ELECTRIC THRUSTERS

The same propeller as the 1002 series, the H106 series electric thrusters are a smaller version for customers that need a smaller lighter more compact thruster with the cost of reduced efficiency. Learn more about our H106 Series Electric Thrusters here.